Why Choose Microtex Cut-Resistant Gloves? | GLOVETEX.COM

Why Choose MICROTEX?

Today, I'd like to highlight the strengths and advantages of MICROTEX protective gloves. Here are some key points that professional craftsmen consider when choosing them:

Thai Brand with Innovation: MICROTEX is a Thai brand designed specifically for the needs of Thai users. It emphasizes innovation to cater to the demands of local professionals.

Manufactured in Thailand: Being the only brand manufacturing protective gloves in Thailand, MICROTEX ensures quality control and local production, which is appreciated by craftsmen.

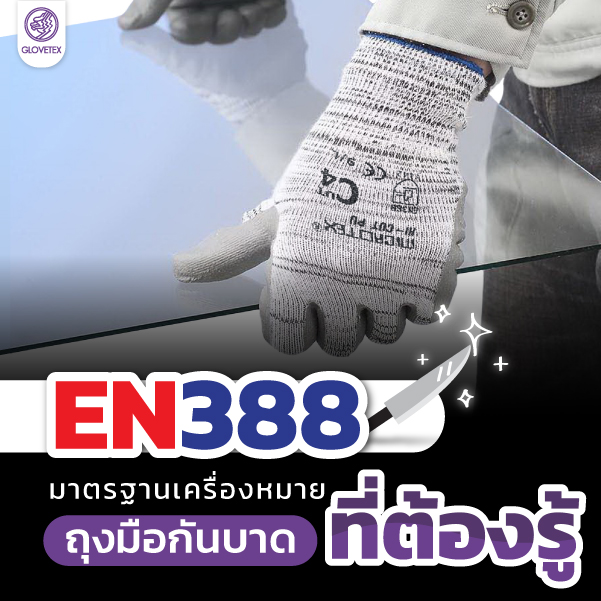

Certified Products: MICROTEX products come with certification, and customers can easily inquire about and obtain product certifications. Additionally, MICROTEX is the only brand with its own laboratory, where products are tested in collaboration with international labs.

Tailored Solutions: MICROTEX is responsive to the needs of its users. With manufacturing facilities in Thailand, the brand can adjust and customize product specifications according to specific requirements.

Innovative Yarn Technology: MICROTEX gloves feature innovative yarn technology that is durable, washable, long-lasting, and comfortable to wear without causing irritation.

Today, I'd like to share some interesting features of MICROTEX protective gloves that make them a top choice among professional craftsmen. Let's break it down into key points for clarity:

Injury Protection: MICROTEX gloves are designed to protect against injuries and abrasions. Typically made from high-performance fibers such as Kevlar, Engineering Yarn, or HPPE (High-Performance Polyethylene), they offer excellent resistance to cuts.

Comfort and Flexibility: Engineered for a balance between protection and comfort, MICROTEX gloves are lightweight and flexible. They allow for easy movement and may incorporate ergonomic designs or features to enhance comfort during prolonged use.

Enhanced Grip: MICROTEX gloves may feature technologies or coatings to improve grip, aiding in better control and grip strength. This is particularly beneficial in tasks requiring secure handling, such as managing sharp objects or working in wet or oily conditions.

Durability: Generally, MICROTEX gloves are designed to be durable and have a long service life. They often withstand abrasion well, ensuring longevity even under heavy usage.

Versatility: MICROTEX brand gloves are suitable for various industries and applications, including manufacturing, construction, automotive, glass handling, metalworking, and more. They are ideal for tasks involving sharp objects, machine operation, or activities with a risk of cuts or abrasions.

The Significance of Cut-Resistant Gloves: Hand Protection in High-Risk Environments

In various industries, workers often face potential dangers that could lead to serious injuries, particularly to their hands. One effective way to mitigate these risks is by using cut-resistant gloves. These specialized gloves provide critical protection, guarding against cuts and lacerations while enabling workers to perform their tasks with confidence and safety. In this article, we will explore the importance of cut-resistant gloves and the industries where they are indispensable.

Increased Safety: Cut-resistant gloves are designed to withstand sharp objects such as knives, blades, and glass or metal shards. Wearing these gloves significantly reduces the risk of severe injuries or lacerations, acting as a protective barrier against potential dangers. This helps to minimize accidents and injuries.

Enhanced Work Efficiency: When employees feel safe and protected, their work efficiency naturally improves. Cut-resistant gloves enable workers to focus on their tasks without worrying about potential accidents that could occur at any time. Providing suitable protective equipment allows employers to create a more efficient working environment, where employees can work quickly and confidently.

Applications Across Industries:

a. Construction and Manufacturing: In various industries such as construction, manufacturing, and metalwork, workers often handle sharp tools and machinery. Cut-resistant gloves help prevent injuries and cuts without compromising the ability to handle materials and equipment safely.

b. Food Processing: In the food processing industry, cut-resistant gloves are essential for workers handling knives or working with meat, fish, and poultry. These gloves not only protect against cuts but also reduce the risk of contamination, promoting food safety and hygiene.

c. Automotive and Glass Industry: Mechanics and glassworkers frequently encounter sharp edges and broken glass. Cut-resistant gloves are invaluable in these industries, protecting workers' hands from potential injuries while maintaining dexterity and grip.

- Compliance with Safety Standards: Using cut-resistant gloves not only prioritizes the safety of employees but also ensures compliance with regulations and safety standards set by regulatory agencies. Employers who provide suitable protective equipment demonstrate a commitment to their workers' well-being and mitigate potential legal issues.

information. or request a quotation

Call Center: 034-878762 ext. 3

Or you can follow us at : Click here

Hotline 083 989 7512 (telephone sales department)