TOWA ActivGrip Advance KEV 591 vs PowerGrab® Katana 310

TOWA ActivGrip Advance KEV 591 VS TOWA PowerGrab® Katana 310: Comparing Industrial Gloves

Overview of TOWA Gloves

Features of TOWA ActivGrip Advance KEV 591

This model combines MicroFinish® technology with Kevlar® fibers, a material known for its resistance to cuts and heat. Its key features include:

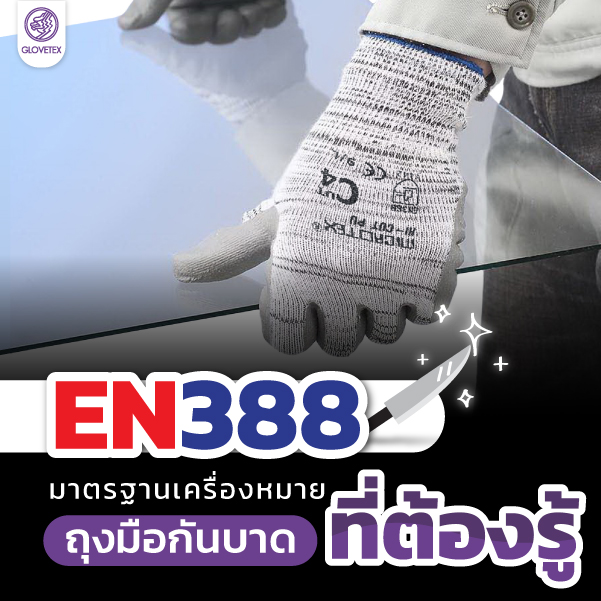

- Moderate Cut Protection

- Made with 13-gauge Kevlar®, it offers CE EN 388 Cut Level 3 (or ANSI Cut Level A2) protection, ideal for tasks involving moderate cut risks, such as metal or glass cutting.

- Excellent Grip in Wet and Oily Conditions

- Featuring MicroFinish® and a double Nitrile coating, these gloves provide a secure grip even in environments with oil or liquids, reducing the risk of objects slipping.

- Flexibility and Breathability

- Designed with an open-back structure and lightweight materials, they minimize hand fatigue and moisture buildup, making them suitable for prolonged use, such as in automotive assembly.

- Oil Penetration Resistance

- The Nitrile coating prevents oil and chemicals from seeping through, keeping hands clean and safe during use.

Ideal Applications:

- Automotive or electronics assembly plants

- Tasks involving oil or liquids

- Jobs requiring precision alongside moderate cut protection

Limitations:

- Cut protection is moderate, making it less suitable for high-risk tasks like heavy metal cutting.

Features of TOWA PowerGrab® Katana 310

This model is built for maximum protection, blending Kevlar® with steel fibers and coated with latex. Its standout features are:

- Maximum Cut Protection

- Constructed with 10-gauge Kevlar® and steel fibers, it achieves CE EN 388 Cut Level 5 (or ANSI Cut Level A4-A5), perfect for high-risk tasks like cutting glass or heavy metal.

- Grip in Dry and Wet Conditions

- The crinkle-finish latex coating ensures excellent grip, especially for handling large or slippery materials like glass or wood.

- Moderate Heat Resistance

- Capable of withstanding moderate heat, it’s suitable for tasks involving warm components, such as metal casting.

- High Durability

- With a thicker structure and double-coated thumb area, these gloves are built to last in rugged, heavy-duty applications.

Ideal Applications:

- Glass or metal manufacturing plants

- Construction or woodworking

- Tasks requiring top-tier cut protection and heat resistance

Limitations:

- Thicker and heavier than ActivGrip Advance KEV 591, making it less ideal for tasks needing flexibility or fine dexterity.

- Reduced breathability may cause discomfort during extended wear.

Comparison Table: ActivGrip Advance KEV 591 vs PowerGrab® Katana 310

|

Feature |

ActivGrip Advance KEV 591 |

PowerGrab® Katana 310 |

|---|---|---|

|

Main Material |

Kevlar® 13-gauge |

Kevlar® + Steel 10-gauge |

|

Coating |

Nitrile (MicroFinish®) |

Latex (Crinkle Finish) |

|

Cut Protection Level |

CE Cut Level 3 / ANSI A2 |

CE Cut Level 5 / ANSI A4-A5 |

|

Grip Performance |

Excellent (dry/wet/oily) |

Excellent (dry/wet) |

|

Flexibility |

High (light and thin) |

Moderate (thicker) |

|

Breathability |

Good (open-back) |

Moderate |

|

Heat Resistance |

Low |

Moderate |

|

Ideal Tasks |

Precision/oily tasks |

Heavy-duty/metal/glass tasks |

Purchasing Guidelines for Factories

For procurement teams and decision-makers, selecting the right gloves depends on the nature of the work and budget considerations:

- For Factories Focused on Flexibility and Oil Exposure

- ActivGrip Advance KEV 591 is the better choice due to its lightweight design, breathability, and excellent oil resistance—ideal for assembly or precision tasks.

- For Factories Prioritizing Heavy-Duty Protection

- PowerGrab® Katana 310 excels with its maximum cut protection and durability, making it perfect for high-risk tasks like metal or glass handling.

- Budget and Longevity Considerations

- ActivGrip Advance KEV 591 is more cost-effective for general use, while PowerGrab® Katana 310, though pricier, offers long-term value for demanding applications.

- Employee Needs

- If workers need comfort for all-day wear, ActivGrip is preferable. For maximum safety in hazardous conditions, Katana is the go-to option.